The “Rubber Band” of the Spring Industry: Ultra-Flexible Extension Spring Redefines Application Boundaries with 300% Stretchability

Publish Time: 2025-10-23

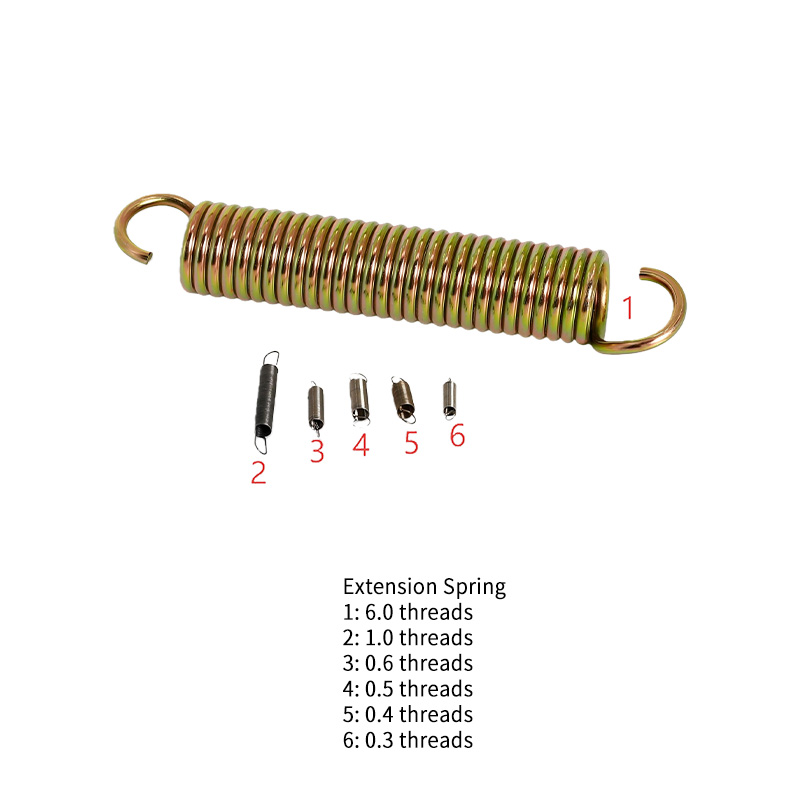

In the fields of mechanical transmission, home appliances, electronic devices, and even crafts, the flexibility and stability of springs directly determine product performance and lifespan. An ultra-flexible extension spring—hailed as the “rubber band of the spring world”—is revolutionizing multiple industries with its groundbreaking 300% elongation rate and full-scene adaptability. This article explores how this spring, through its flexibility, is reshaping the boundaries of spring applications from three perspectives: technological innovation, application scenarios, and industrial value.I. Technological Breakthrough: A “Flexibility Revolution” from Material to StructureThe 300% elongation rate stems from dual innovations in material science and structural design. Traditional extension springs, often made from carbon steel or stainless-steel wire, typically reach their elastic limits at 150–200%. Beyond this range, they are prone to deformation or fracture. The ultra-flexible spring achieves its superior elasticity through three key technological advances:1. Advanced Alloy Materials:Constructed with high-manganese spring steel (e.g., 65Mn) and silicon-chromium composite alloy wire, the addition of manganese enhances toughness, while silicon-chromium alloys improve fatigue resistance. As a result, the spring maintains an elastic recovery rate of ≥98% even after extensive repetitive stretching.2. Gradient Elastic Design:Employing a “tight–loose–tight” coiling pattern, the spring’s central loose-coil segment absorbs most of the deformation, while the tight ends provide stability and prevent stress concentration. Testing by a home appliance manufacturer demonstrated that this structure extended spring life from 50,000 to 120,000 cycles.3. Surface Reinforcement:Dual protection via zinc-nickel electroplating and Dacromet coating ensures superior corrosion resistance. The spring passes 480-hour salt spray tests (double the national standard of 240 hours), maintaining stable performance in humid or corrosive environments.The “rubber band” metaphor is fitting—the spring stretches with remarkable smoothness and recoils with precision, offering the elasticity of rubber combined with the durability and load-bearing strength of metal.II. All-Scenario Adaptability: The “Universal Spring” for Home, Industrial, and Electronic UseThis spring’s true strength lies in its versatility across industries.Home Appliances: Balancing Silence and DurabilityIn door hinges and damping systems of washing machines and refrigerators, traditional springs often cause stiffness or noise due to limited elongation. The ultra-flexible spring enables smooth cushioning through a full opening range of 30°–180°. In one refrigerator case, door noise was reduced from 45 dB to 28 dB, while user complaints dropped by 60%.Industrial Equipment: The “Stabilizer” Under High-Frequency VibrationApplications such as sensor triggers and valve controls in automation systems require springs to perform reliably under hundreds of vibrations per minute. With its 300% stretch design, the spring absorbs greater displacement energy within compact spaces. A robotic arm manufacturer recorded improved positioning accuracy from ±0.5 mm to ±0.1 mm.Consumer Electronics: The “Elastic Core” of MiniaturizationIn micro devices like Bluetooth earbud cases and smartwatch bands, the ultra-flexible spring achieves a 10 mm stroke with a wire diameter of just 0.2 mm. Copper-iron alloy variants ensure conductivity. After adoption by a leading consumer electronics brand, product assembly yield rose from 82% to 95%, while spring-related defects were completely eliminated.Gifts and Craftwork: The “Elastic Medium” for CreativityFor toys and decorative designs, flexibility itself inspires innovation. One holiday gift design used color-coated springs to create a “stretch–recoil” interactive motion, achieving over 100,000 units in monthly sales.III. Industrial Value: Enabling Cost Efficiency and User Experience UpgradesFor manufacturers and procurement teams, this spring serves as both a performance enhancer and a cost optimizer.Extended Lifespan, Hidden Cost Savings:In home appliance applications, traditional springs require annual replacement. The ultra-flexible variant lasts 3–5 years, reducing per-unit maintenance costs by up to 70%.Greater Design Freedom:The 300% stretch ratio allows engineers to reduce spring count or installation space. One lighting manufacturer replaced three short springs with a single long flexible spring—cutting BOM costs by 40% and achieving a cleaner design aesthetic.Accelerated Customization:OEMs offer rapid prototyping services based on customer drawings or samples. Customization includes wire diameter (0.1 mm–10 mm), material (carbon steel / stainless steel / copper alloy), and surface finishing (zinc / nickel plating / powder coating). One EV manufacturer completed spring development in just seven days, significantly shortening time-to-market.For end users, flexibility directly enhances experience:Home appliance doors open more smoothly; industrial equipment operates more reliably; and consumer devices last longer with fewer failures.IV. Future Trends: The “Intelligent” and “Contextual” Evolution of Flexible SpringsWith advances in IoT and materials science, ultra-flexible extension springs are evolving from passive components to smart elements.Smart Sensor Springs:Using piezoelectric coating technology, springs can now transmit real-time deformation data—ideal for Structural Health Monitoring (SHM) systems.Shape-Memory Alloy Springs:By leveraging nickel-titanium alloys, springs can automatically return to preset shapes after stretching, unlocking applications in medical and aerospace engineering.3D-Printed Metal Springs:Additive manufacturing enables complex geometries—such as honeycomb coils—unachievable through traditional winding, optimizing force distribution and structural efficiency.Industry analysts predict that by 2025, flexible springs with sensing capabilities will capture over 15% of the total spring market, while traditional designs will continue to decline.Defining a New Standard of FlexibilityFrom appliance hinges to robotic arms, from micro-electronic components to creative art pieces, the ultra-flexible extension spring—with its 300% elongation capacity—is establishing a cross-industry application ecosystem. Its significance extends beyond technical performance: it represents a holistic upgrade in cost-efficiency, durability, and user experience.Whether for standard component procurement or customized engineering, this “rubber band of the spring world” is your reliable partner in product innovation—because true flexibility is never compromise, but the ultimate pursuit of performance and perfection.(For design inquiries or samples, contact us today—prototype delivery within 72 hours!)